The COVID-19 pandemic is immensely straining health systems around the world. The supply of personal protective equipment (PPE) is now an urgent priority.

An impressive number of individuals, universities, and private companies have quickly shifted to producing PPE for the health sector.

As face masks and respirators have become challenging to find, the face shield has quickly risen as an alternative [1]

[2] that sits at the intersection of easy manufacturability and effectiveness in preventing the spread of the virus.

Diverse designs made with equally diverse manufacturing processes have appeared. This variety is primarily due to the range of skills and equipment available to producers.

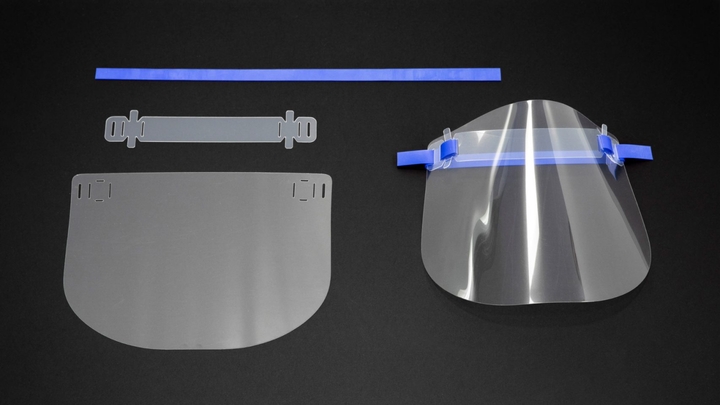

Cut plastic and elastic

Unsurprisingly, the highest-profile company producing face shields is Apple. They now ship out one million a week from factories in The United States and China [3]. Each one consists of two pieces of plastic cut from large sheets, and an elastic strap also cut from a large sheet.

Foster + Partners, the esteemed architecture firm which coincidentally has close ties with Apple, is producing a similar, albeit more complicated design.

This design is quite elegant for two reasons. First, since all parts are cut from large sheets, manufacturing time is quick. Even at a small scale, laser cutting and die cutting are much faster than 3d printing. Second, like many of the other designs in this list, the shields can be flat packed, which optimizes their volume when shipping.

3d printed

3d printing, which was initially limited to small-scale rapid prototyping, has become a large-scale manufacturing technique of its own across industries. Naturally, many companies with 3d printing capabilities are shifting their printers to face shield production.

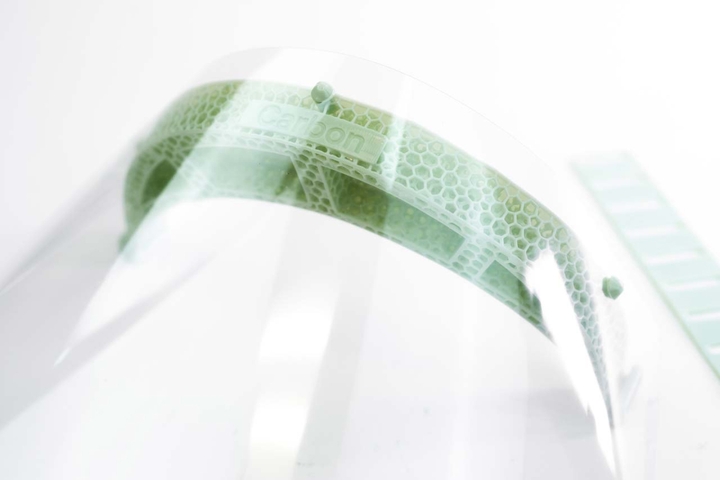

One of those companies is Carbon. They produce a 3d printed midsole for the Adidas 4D [4] line of running shoes. Carbon and Adidas’s face shield design involves a flexible, 3d printed headband, to which a thin plastic visor is attached.

The headband has a hollow cellular structure that is strong while reducing both material use and print times [5].

While Carbon is using a stereolithography (SLA) process, I have seen hobbyists and larger organizations alike using every other major 3d printing technology.

Injection-molded headbands

3d printing offers a lot of flexibility since one machine can produce a variety of objects from many different materials. Yet, injection molding is considerably quicker and more economical at scale. Parts are produced by injecting molten plastic into a metal mold. The marginal cost of each piece is cheap. There is, however, a considerable upfront cost for the mold. So, injection molding only makes sense at larger scales.

Fictiv, which specializes in on-demand manufacturing, is one of many companies that have already made [6] the required tooling to begin manufacturing shields quickly.

Foam headband

At this point, you have likely noticed a pattern here. Face shields tend to be made from three distinct parts: a clear plastic visor, a headband, and a strap around the head.

Members of a makerspace at the University of Wisconsin—Madison designed an elegant solution that uses a thick piece of foam as the headband, to which a strap and plastic visor is attached. Ford has taken this design and is manufacturing them at scale [7].

Nike has created a similar solution using materials at their disposal [8]: clear plastic normally used in Nike Air bags, and foam and cords with toggles from jackets.

Improvised

Another style is more of an improvised design. Some people are making clips that help attach a visor to a standard baseball cap. Japanese designer Tokukin Yoshioka devised a similar, yet even simpler solution using a pair of eyeglasses and a single sheet of plastic. He cut out the shape of the visor and two holes for either temple to go through.

Single material

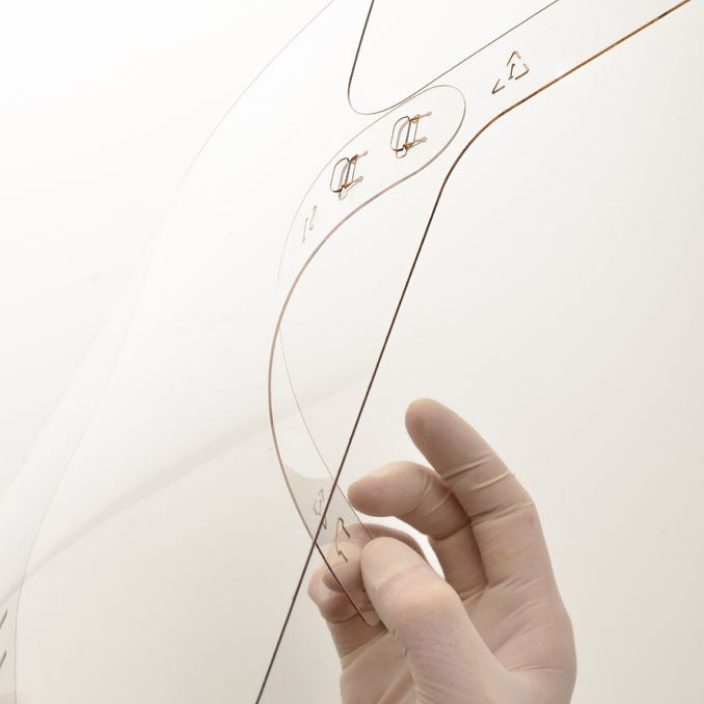

The last class of face shield I have noticed is made from a single material, usually cut plastic. Design Friction Lab has created a design that is assembled from a few parts, all cut from the same sheet of plastic.

MIT and the University of Cambridge have each created their own design that folds together origami style. MIT’s version impressively comes together from a single piece of plastic.

Adversity breeds creativity

What this pandemic has revealed is that humanity, when faced with a threat, can apply its ingenuity towards creative solutions. Whether it’s a hobbyist at home printing out face shields one by one or a multinational corporation flexing their whole supply chain to produce them by the millions, each has their own way that they are helping.

The multitude of designs proves that there is no one right way. Every contributor can draw on their unique set of materials, knowledge, and tools at their disposal.

It’s the most beautiful side of design that I have seen in years.

- Strategies for Optimizing the Supply of Facemasks · CDC ↩︎

- Guidance on Preparing Workplaces for COVID-19 · OSHA ↩︎

- Tim Cook on Twitter ↩︎

- Carbon lattice innovation — the adidas story · Carbon ↩︎

- Carbon COVID-19 Response · Carbon ↩︎

- COVID-19 Face Shields · Fictiv ↩︎

- Medical face shield designed by UW-Madison engineers, design firm being made globally · WISN ↩︎

- Nike designs personal protective equipment for Oregon hospitals · Dezeen ↩︎

Thanks to Q for reading drafts of this.